Factory Acceptance Test Checklist, Https Www Lockheedmartin Com Content Dam Lockheed Martin Eo Documents Suppliers Rms Rms Quality Fai Pdf

Factory acceptance test checklist Indeed recently is being hunted by consumers around us, perhaps one of you personally. People now are accustomed to using the internet in gadgets to see image and video information for inspiration, and according to the name of the article I will talk about about Factory Acceptance Test Checklist.

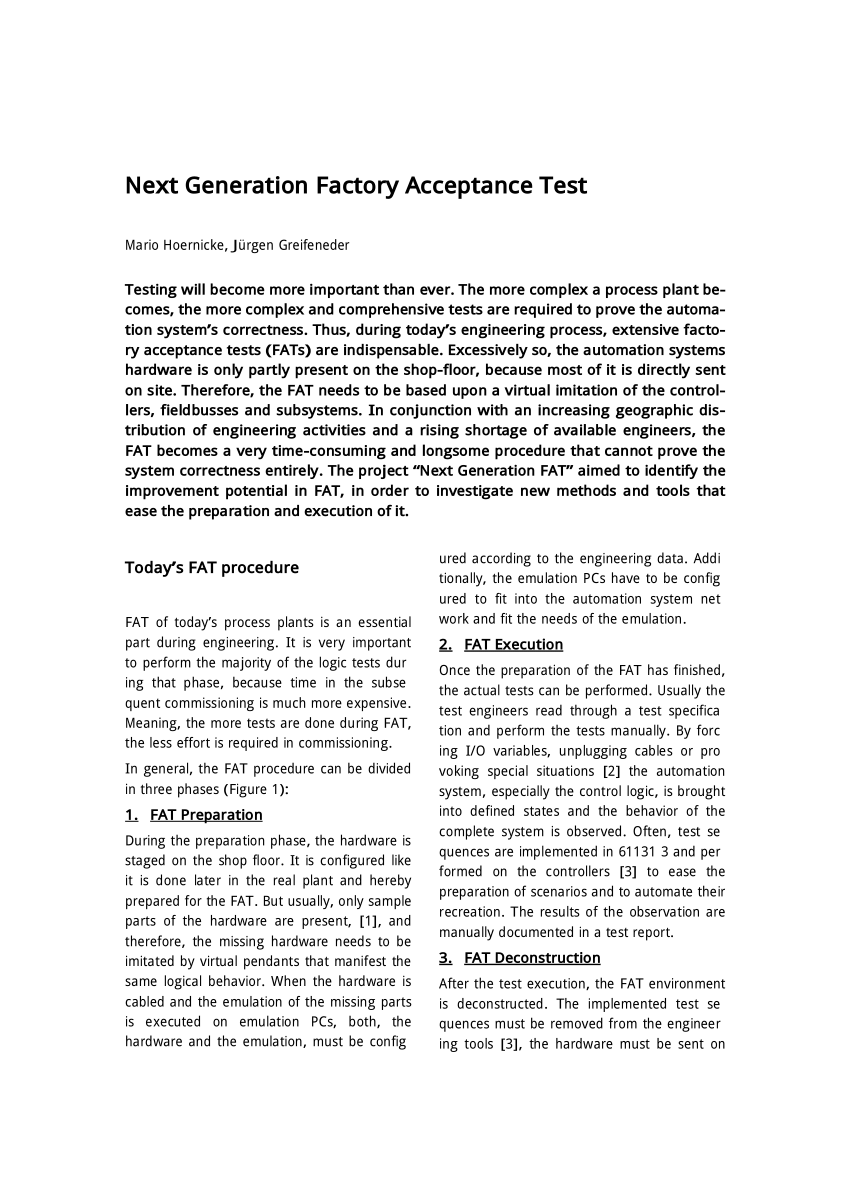

- Factory Acceptance Test Fat Pharmaceutical Guidelines

- Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcslm7jligyhkqnp Iiyshvzax7dgf4 Uyhgd3dwjup62h22ukje Usqp Cau

- Https Oaktrust Library Tamu Edu Bitstream Handle 1969 1 162538 Pumptutorial1 Pdf Sequence 1

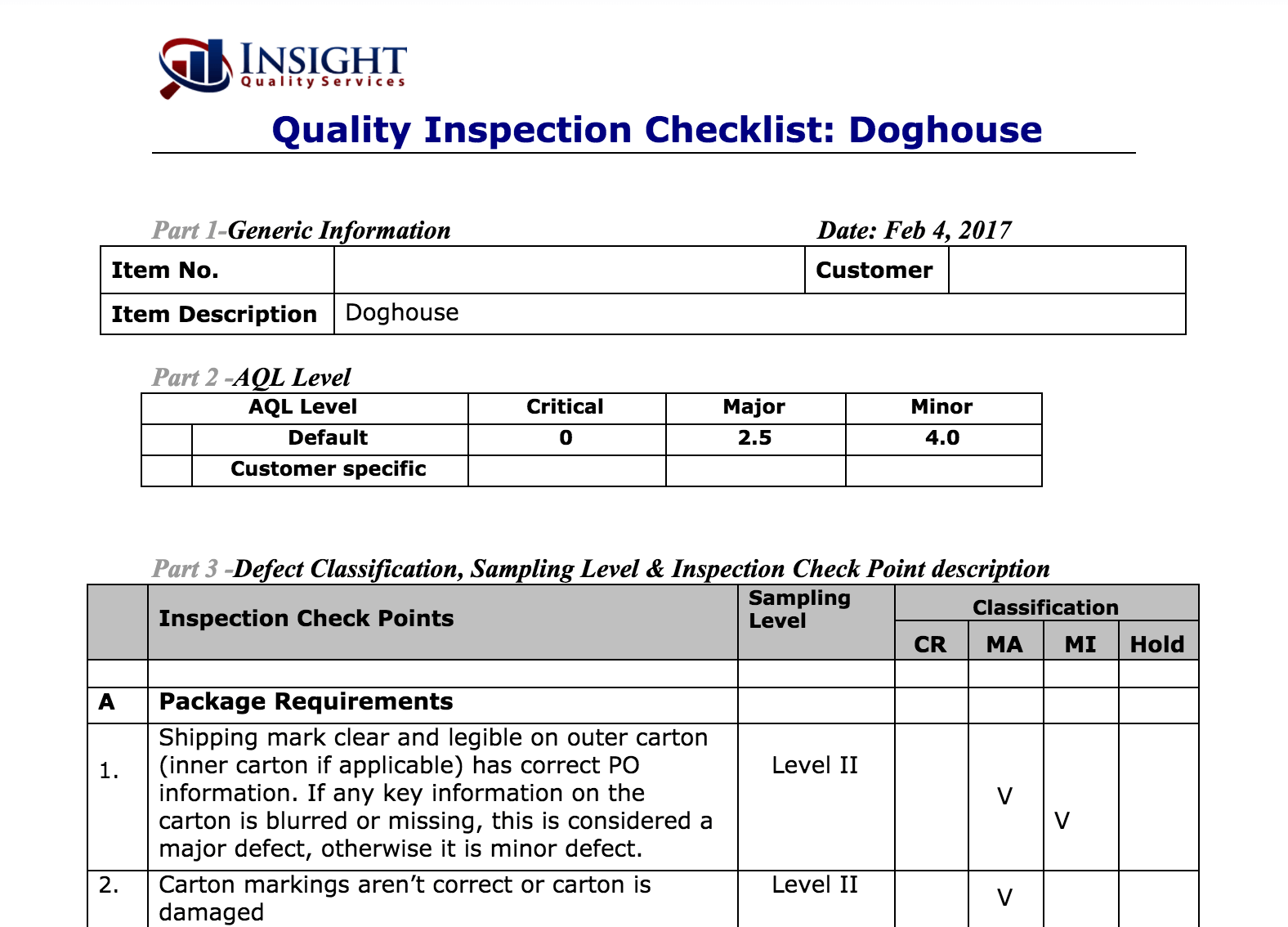

- What Is A Quality Control Inspection Checklist How To Prepare A Qc Checklist

- Factory Acceptance Test Fat Pharmaceutical Guidelines

- What Is A Quality Control Inspection Checklist How To Prepare Qc Checklist

Find, Read, And Discover Factory Acceptance Test Checklist, Such Us:

- Factory Acceptance Tests What They Are And Why They Re Important

- Https Www Lockheedmartin Com Content Dam Lockheed Martin Eo Documents Suppliers Rms Rms Quality Fai Pdf

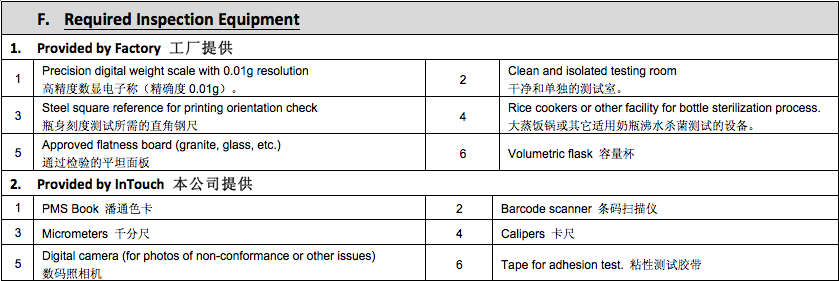

- Trip To China 3000 Vs Factory Inspection 70

- Inspection Defect Checklist For Fabric Apparel Manufacture

- Https Www Lockheedmartin Com Content Dam Lockheed Martin Eo Documents Suppliers Rms Rms Quality Fai Pdf

If you are searching for Factory Girl you've reached the right location. We have 104 images about factory girl adding pictures, photos, pictures, wallpapers, and much more. In such page, we additionally provide number of graphics available. Such as png, jpg, animated gifs, pic art, symbol, black and white, translucent, etc.

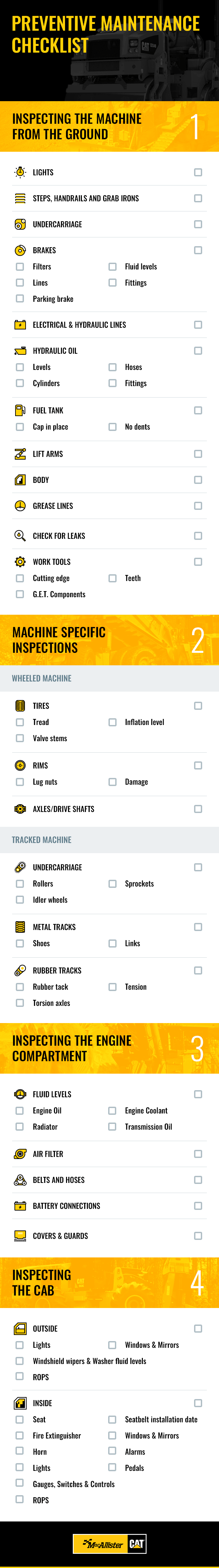

If a checklist is used for factory acceptance costly project delays can be avoided.

Factory girl. Why is a checklist used for a factory acceptance test. The factory acceptance testing process. Factory acceptance testing level 1 fat overview a level 1 fat is the most basic level of equipmentsystem testing conducted at the oem.

A fat protocol can be written as follows. This is often the level of acceptance test for equipment that is similar to other equipment in the plant or for equipment that has simple to moderate upgrades andor modifications. While keeping in mind that no two are alike here is an example to give you a better idea of the inspection points and tests that are used to validate the equipment.

Its hard to outline exactly what a factory acceptance test consists of because each one is unique to the equipment it involves and the specialized requirements of the customer. This is done by ensuring the completion of the fat protocol such as standard operating procedures welding process qualifications and certificates of conformity and the implementation of the correct test. Use this factory acceptance test fat checklist to document the completeincomplete fat protocol capture photo evidence of the entire fat procedure including hazard identification safety inspection and ergonomic assessment specify the passfail acceptance criteria upon the actual fat assign corrective actions for equipment nonconformities and validate the factory acceptance test with.

A proper fat can help to minimize the problems occur during the installation of the equipment at the site. The product must be assembled prepared and connected to utilities for testing. Factory acceptance test fat test the factory acceptance test fat refers to the functional test that is performed by the vendor upon completion of the manufacturing process to prove the equipment has the same specification and functionality that indicated in the datasheet specification and purchase order.

Documentation such as drawings asme certificates and test procedures must be gathered. Using a factory acceptance test checklist can reduce costly project delays by ensuring the completion of fat protocol such as standard work procedures certificates of compliance and welding processes qualifications and implementing the proper factory acceptance test procedure. A factory acceptance test is a major project milestone where a piece of equipment is demonstrated to meet the contract or purchase order requirements specifications which are usually created by a systems owner project manager or project team.

This factory acceptance testing checklist is free to use and makes fat checklists easy to complete track and share. Factory acceptance test fat is done at the equipment manufacturing site of the vendor before the shipping. There are several components that make up fat.

More From Factory Girl

- Factory Hiring Near Me

- Factory Game Pc

- Factory Data Reset Stb Indihome

- Factory Quarter W3

- Factory Nike

Incoming Search Terms:

- How To Prepare For A Factory Acceptance Test Fat Factory Nike,

- Https Www Cibse Org Getattachment Networks Regions Home Counties Ne Hcne Past Presentations Cibse Hcner Commissioning Management Presentation Pdf Aspx Factory Nike,

- Trip To China 3000 Vs Factory Inspection 70 Factory Nike,

- Transformer Factory Acceptance Tests Factory Nike,

- Free Printable Furniture Quality Control Checklist Template Checklist Templates Factory Nike,

- Http Files Allpax Com Allpax Factory Acceptance Tests Pdf Factory Nike,